Evolving: Racing seats Evolving: Racing seats

Passing on knowledge about seating technology in motorsport: as part of the Nürburgring Endurance Series, Sascha Taubert answered questions from teams and drivers.

Racing does not only mean speed, but also safety. High standards must be met in order to protect the drivers behind the wheel in the best possible way. “The seats are playing an increasingly important role,” says Sascha Taubert. “We see that more and more racing series are implementing regulations for the use of racing seat shells. The design and selection of the materials used in racing seats are therefore increasingly decisive as to whether they can be used at all.

Sharing knowledge

“We go to great lengths to not only meet these requirements, but to exceed them. From the individual measurement of the driver via a ‘fitting’ to precise 3D scans, which provides the data basis for each seat shell, to the selected materials and a high-quality finish,” explains Sascha Taubert. However, this requires years of development and the experience gained from it – invaluable knowledge that soft trim shares at the racetrack.

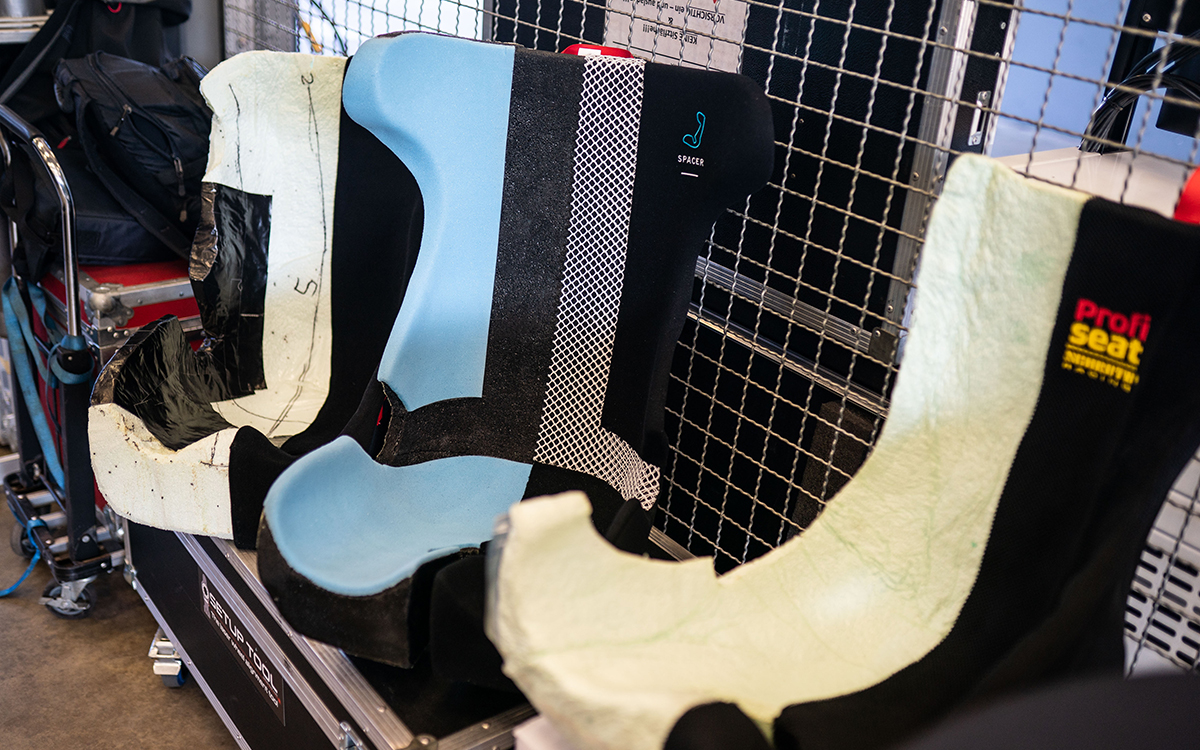

This is what happened at a workshop organized by NIMEX for racing teams and amateur racing drivers at the Nürburging. Among other things, the goal was to show the different steps of the ‘seat fitting’. “So-called ‘wetseats’ are the first choice for many teams to quickly produce a shell and record the driver’s seat impression,” explains Matthias Burghoff. As Managing Director of NIMEX, he supplies motorsport customers throughout Europe with equipment and therefore knows the industry very well.

"Wetseats" also possible as a base

Handcrafted ‘wetseats’ are ideal for use in race cars, but also serve as the basis for industrially produced seat shells such as the SPACER. “By now, we have had very good experiences in terms of manufacturing high-quality seats,” says Sascha Taubert. “Teams send us their shells, from which we then create a digital image using a 3D scan. This is followed by the further production steps up to the delivery of the finished SPACERS in safe, FIA-approved material with all its comfort, stability and climate properties.”

In addition to the reproducibility with the help of seat information stored in the database, which can be read using an attached QR code, the material is one of the greatest advantages. The SPACER meets the requirements for seat inserts of the automobile associations such as the FIA. These are already mandatory in professional racing series such as the World Endurance Championship (FIA WEC).

Convinced? For more information and inquiries about SPACER, check out spacer.soft-trim.de.