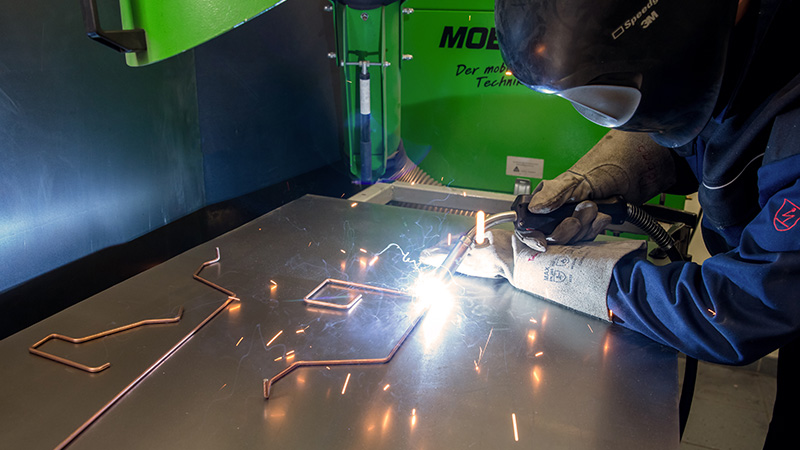

Metal Construction

Staying in the frame. Staying in the frame.

What is it you need? Seat frames, arm rest frames, wire frames for side valanaces , headrests, side-bolsters, tubular frames, head restraint brackets.

We can produce your wire frames, for example for backseat cushions or side bolsters. Even integrated directly into your foam or EPP parts.

Typically soft trim: to ensure maximum accuracy, we produce individual CNC-milled 3D welding fixtures. And using CNC technology to integrate your wire frames into the foam or EPP parts gives the highest level of precision in every part. We can work with wire of different grades and surfaces and in all common sizes.

-

Inquiry

-

arrow DocumentsWe provide secure data lines to ensure the problem-free uploading of specifications for your spec sheets, part fact sheets and CAD data. -

arrow DeadlinesThings can go quickly: we are able to fulfill even short turnaround times, working with you to determine order priorities. -

arrow CostsIn the bid phase you’ll see that we are open to negotiations that will give you the best price possible. It’s a principle of ours to optimize costs and offer attractive terms to all our clients.

-

-

Metal Construction

-

arrow MaterialsWhat materials do want? We work with different grades of material, surfaces and sizes – practically anything goes. -

arrow CAD-DesignSeat frames, armrest frames, wire frames for side valanaces, head- and side rests, tubular frames, head restraint brackets, central armrests – and much more. We can produce them all. -

arrow CAM-ProgrammingWe create the milling programs we use to produce welding fixtures ourselves on the basis of CAD data sets. This guarantees a consistently high level of quality. -

arrow Metal ConstructionWe can separate, bend and weld to precise templates and to the most exacting of standards: our metal construction department will produce wire frames exactly to your needs. -

arrow Model MakingWe can integrate your wire frames into foam or EPP-milled parts, as you require. If necessary, we can combine these processes. -

arrow Optical Measurement / Reverse EngineeringWe scan your component parts – and generate data for manufacturing. Or we can scan already finished parts for reverse engineering to inspect their contours.

-

-

Final Inspection / Quality Control

-

arrow Final InspectionDuring final inspection, each individual component is carefully checked – a process which is carefully documented, in writing and with photos. -

arrow Quality AssuranceEach part is subject to ongoing quality control. They are then individually labeled and completely traceable. Naturally, you receive complete documentation on this process.

-

-

Shipping

-

arrow AsapYou can depend on the quickest possible delivery at the best possible price. We will meet your deadline.

-