Show car interior

We speak design. We speak design.

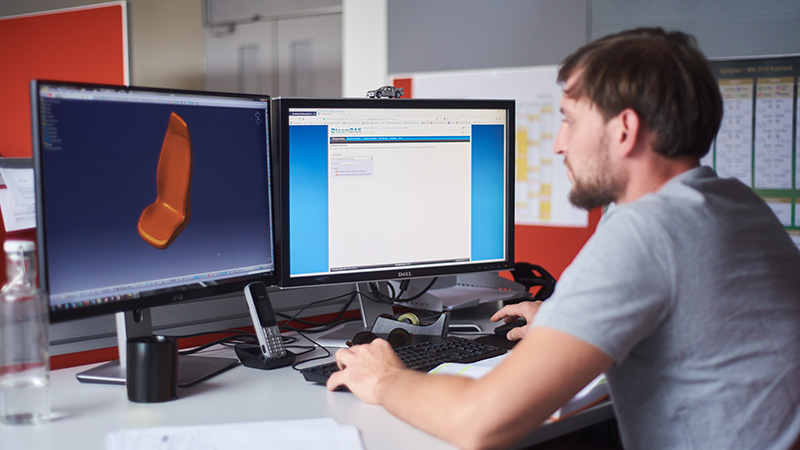

Anyone working with designers needs to be able to understand and apply contemporary stylistic elements. We can and we do. In fact, it’s why our show car interiors are so aesthetically convincing, right down to the smallest detail.

Equally important is craftsmanship. From foam milling through to the final seat, we carry out every step in the creation of complete seats. Planning, optimization, producing any necessary parts, painting and laminate. From start to finish, we are there.

And if a problem arises, we find solutions – and fast. Whether it’s hard or soft parts, we can handle them all. And produce any interior component your job might need. To the highest specifications.

-

Inquiry

-

arrow DocumentsWe provide secure data lines to ensure problem-free uploading of specifications for your spec sheets, part fact sheets and CAD data. -

arrow DeadlinesWe set project milestones with you. And have all the necessary capacities, skills and experience to meet them right here in our facility. -

arrow CostsIn the bid phase you’ll see that we are open to negotiations that will give you the best price possible. It’s a principle of ours to optimize costs and offer attractive terms to all our clients.

-

-

Conception

-

arrow SourcingWe will order or produce the necessary structures, upholstery, hang-on parts, laminates and foams. -

arrow FeasibilityWe find solutions to make sure that your desired functionalities and designs are realized – no matter how challenging. -

arrow MaterialsInnovative materials require design-compatible processing procedures. We find them using perforations, welding and other creative solutions. -

arrow CAD-DesignWorking closely with your engineers, we work out your component geometry on the basis of your Class-A surfacing and design data. -

arrow Trim-DevelopmentWe work exclusively digitially – without hardcopy pattern sets. We generate the first pattern set as a CAD file based on your Class-A surfacing or foam data. This allows our staff to create your first presentation sample as quickly as possible. Our CAD-design and foam part production processes run in parallel leading to greatly reduced development time. -

arrow 3D PrintingUsing our own large format 3D printer, we can produce your panels, supports and fixtures – up to a size of 1m3. Full product finishing included. -

arrow Milled PartsMilled foam and EPP parts can be manufactured to your specs. -

arrow Metal StructuresWith your CAD models as templates, we can produce highly-precise metal concept structures using CNC-milled welding fixtures. -

arrow Complete Seats / Optical MeasurementWe use your design guidelines to create your complete seat: optically measured and seamlessly documented. -

arrow PersuasiveWe can give presentations to decision makers and support you with customer reviews – by providing issue lists and working together to determine next steps. -

arrow WorkshopsProductive, innovative, even on the fly: we can organize development workshops which lead, thanks to our physical models, directly to solutions.

-

-

Trade Fairs / Board Presentations

-

arrow SupportWe are there to support you at trade fairs: with the installation and maintenance of your display models.

-