Trim development

100% digital 100% digital

From the initial design through to support when you begin production, we are there every step of the way. Serving your brand, your design and your customers. soft trim is dedicated to ensuring our products can be produced on a mass scale. To meeting every demand of your design. To comfort, quality and optimizing costs. We are at your side at every stage of the process, from start to finish.

Digitizing all our processes has shortened development times dramatically. From the initial design analysis, to assembly and cushioning, we are focused on what counts: product optimization and production feasibility. And every developmental stage is seamlessly documented, accessible at any time.

It’s not just a question of standards, but qualifications. Every one of our seat cover developers is not only a skilled craftsperson, but also masters of the relevant CAD software. This allows them to be able to create initial patterns and BOMs on the basis of Class A surfacing or foam data. These pattern sets form the basis of every subsequent step in the digital development process.

As your partner, we are at your side. Our experienced project managers are there to support you from the first developmental stages right through to the start of large-scale production. And once this is up and running, we will provide workshops and training seminars in your sewing or JIT-factories worldwide.

-

Inquiry

-

arrow DocumentsWe provide secure data lines to ensure problem-free uploading of specifications for your spec sheets, part fact sheets and CAD data. -

arrow DeadlinesWe set project milestones with you. And have all the necessary capacities, skills and experience to meet them right here in our facility. -

arrow CostsIn the bid phase you’ll see that we are open to negotiations that will give you the best price possible. It’s a principle of ours to optimize costs and offer attractive terms to all our clients. -

arrow Concept AnalysisWe analyse the feasibility of your design, collision test it and, if the need arises, develop alternative ideas. -

arrow SourcingWe will order or produce the necessary structures, upholstery, hang-on parts, laminates and foams.

-

-

Development

-

arrow Virtual PrototypingFor the first prototype, we will generate an intial pattern set digitally based on your Class-A surfacing or foam data. -

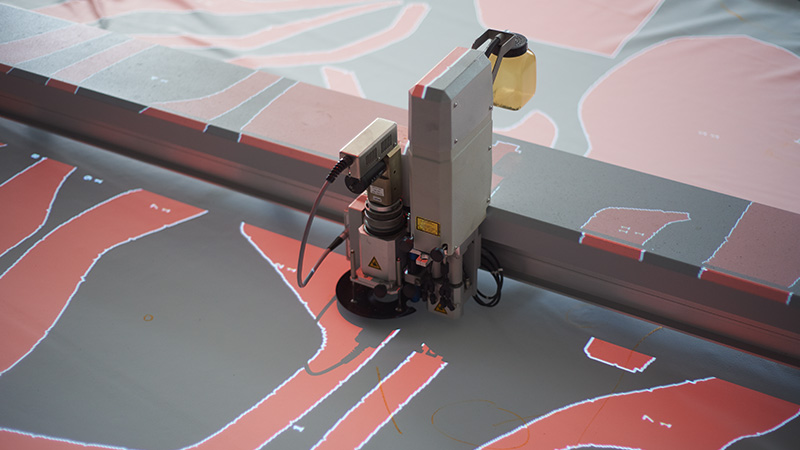

arrow Digital DevelopmentOur work processes are digital-based – with no use of hard copy pattern sets. Every work stage is done digitally. -

arrow CuttingIt’s a time saver: all pattern sets go straight from the developers to the cutter – no manual cutting involved. -

arrow Sewing WorkshopIn our sewing shop we produce your development covers. In doing so, we directly check the industrial feasibility. -

arrow Cover TestingUsing our test covers, you can take care of every construction and integration step: PV-testing, DV-testing, SAB-testing, PVS, etc. -

arrow Development And UpholsteryWe carefully follow your templates. Every step of the process is seamlessly documented and the final result subject to our rigorous quality control regimen. -

arrow Technology Sessions / WorkshopsProductive, innovative, even on the fly: we can organize development workshops which lead, thanks to our physical models, directly to solutions. -

arrow Customer PresentationsWe can give presentations to decision makers and support you with complete documentation including scans, complete sectional maps, etc. -

arrow ScanningHave you reached the stage of Class-A scanning? Our highly-precise 3D scans can make sure that your design is in perfect order – at every stage of the development loop.

-

-

Approval procedure

-

arrow Release DocumentationWhether it’s a P-, a B- or a “soft approval”, we offer you cover sketches, reserve samples, pattern sets, BOM’s, sewing instructions, etc. -

arrow ApprovalsOn the way to production: we can produce complete seats and take part in technical meetings and cover approval processes.

-

-

Industrialization

-

arrow Documentation TransferWe will provide your sewing facilities with complete documentation – comprehensive and in digital format. -

arrow On Site Support / WorkshopsWe are there for you when production starts, to help with training, for process optimization. At suppliers or anywhere you need us. Worldwide.

-

-

SOP - Start of Production